Joint of metal sheet

You are located at:首页ProductSheet metal automationJoint of metal sheet

Joint of metal sheet

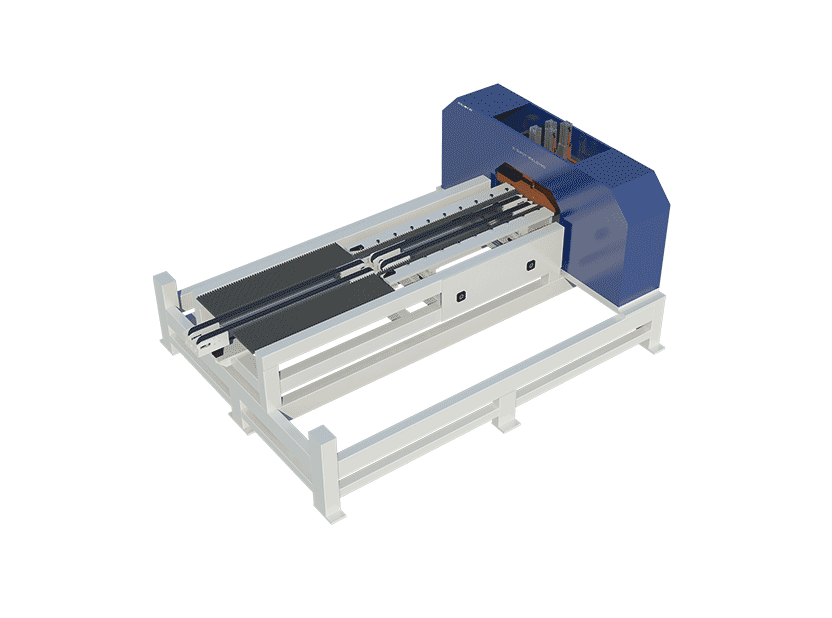

Spot welding connection

The figure shows a spot-welding template for an elevator door panel designed for Hallmark. It can rapidly weld upper and lower door seals and reinforcing ribs of the workpiece simultaneously so as to satisfy product requirements for production takt.

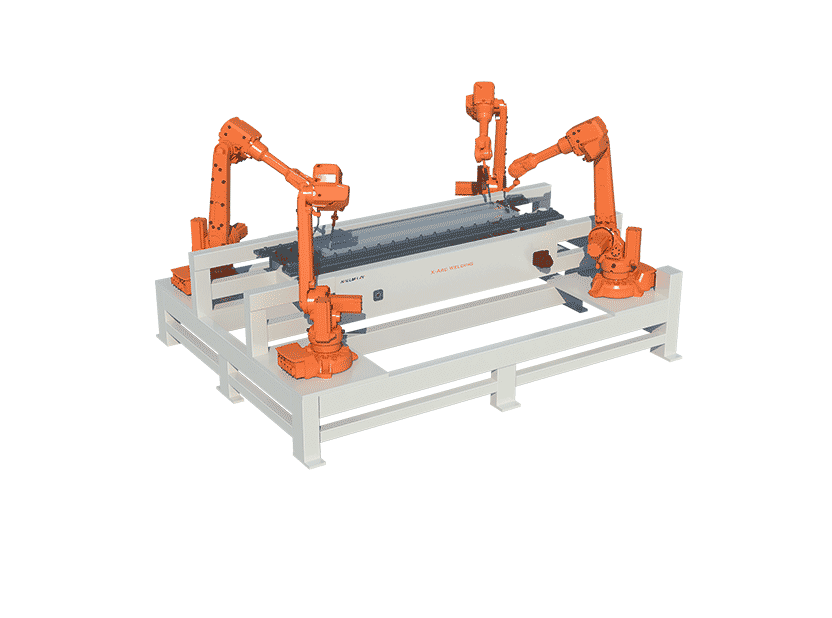

Arc welding connection

Arc welding usually combines a robot to realize automation. Welding robot can realize 24h production and improve production efficiency; meanwhile, it can stabilize and improve welding quality and guarantee its homogeneity; improve labor conditions and can operate under hostile environment for a long term; it can realize automatic welding of batch products.

Rivet-free connection

Rivet-free connection uses plate press-connection machine and dedicated connection die to form an inlaid dot with certain tensile strength and shear strength and without stress concentration through a transient high-pressure machining process. Rivet-free connection is advantageous because it can connect two-layer or multi-layer plates of different textures and different thicknesses, and original cladding layer and paint layer on the plate surface at the connection point will not be damaged.

Adhesive bonding

Triaxial dispensing system of Hallmark is a mature adhesive bonding technology. Adhesive bonding is continuous interfacial connection, which can reduce stress concentration, guarantee strength of the adhered object and length fatigue life of the structural member. Adhesive bonding is very applicable to connection of materials of different textures and thicknesses especially ultrathin materials and complicated structural members.