X-FOLD B workstation

You are located at:首页ProductSheet metal automationX-FOLD B workstation

Four-edge bending solution ——X-FOLD B workstation

X-FOLD A can perfectly solve opposite-edge FOLDing of the workpiece. However, to complete four-edge bending, bending can be carried out only by rotating the workpiece, which will affect fluency of the production line, and X-FOLD B perfectly solves this difficulty.

X-FOLD B workstation is similar to X-FOLD A in principle and performance. The user can select the configuration according to product requirements.

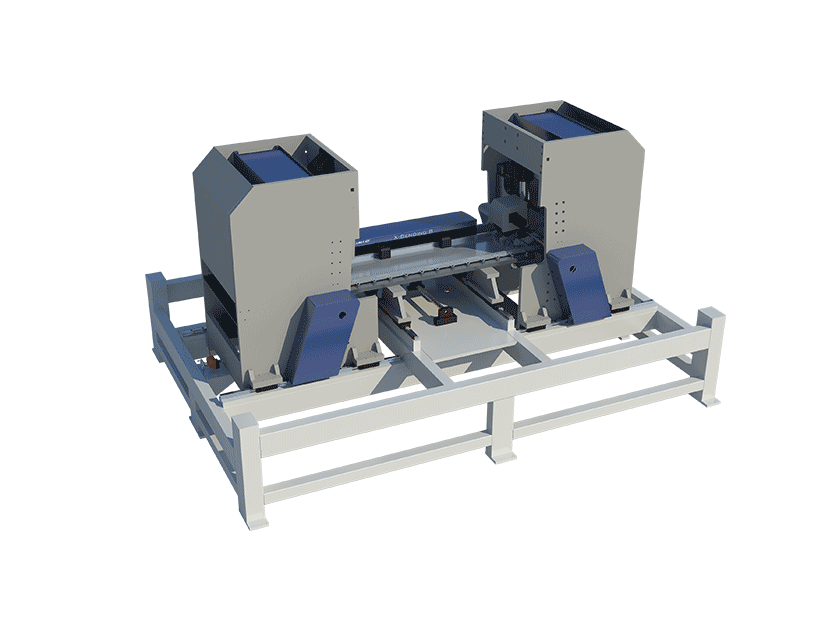

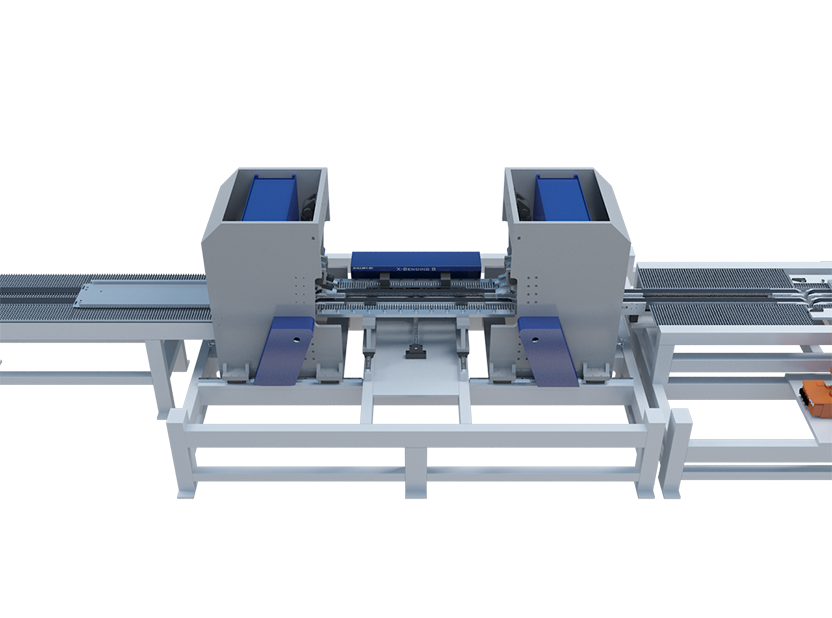

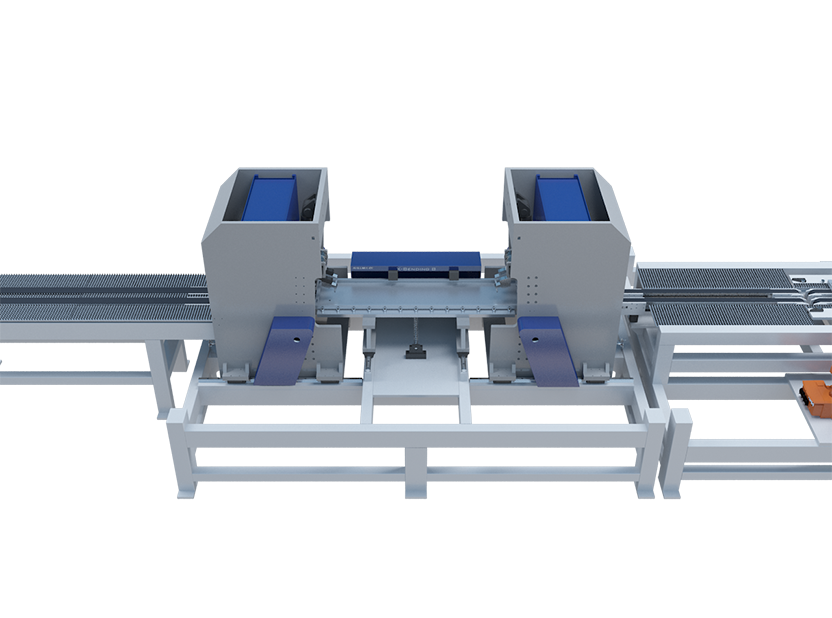

X-FOLD B workstation

As shown in the figure, X-FOLD A workstation consists of precise heavy rack, two edge folding machines, conveying system and control system with small occupation of land and compact structure.

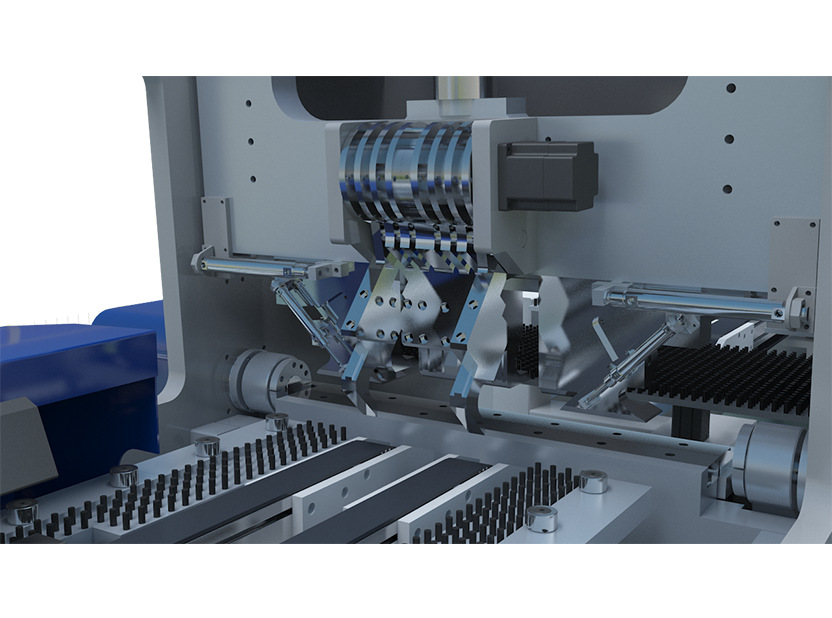

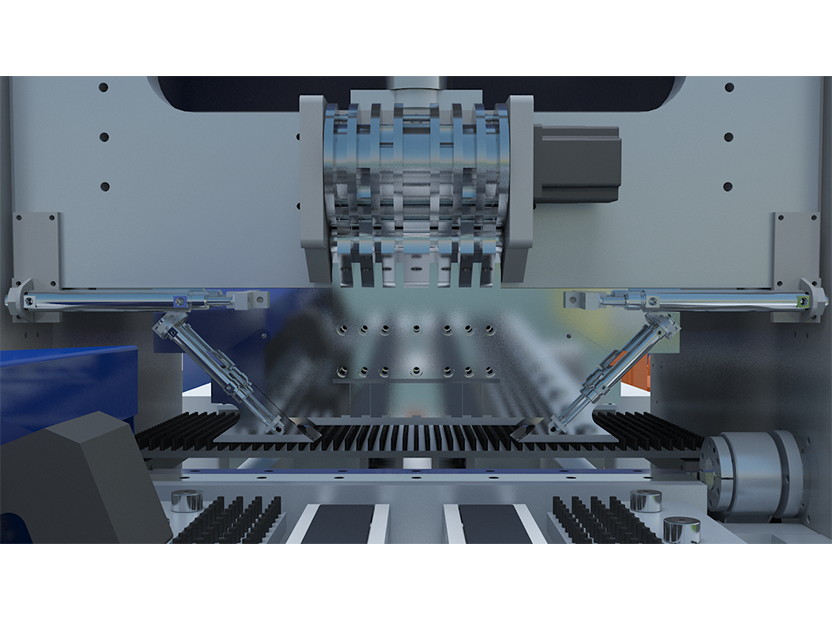

Automatic adjustment of cutting dies

When X-FOLD B is used for four-edge bending, demoulding problem exists at corners. X-FOLD B uses automatic cutting die replacement design, which can not only realize smooth demoulding after bending but also can automatically adjust width of cutting die and bring greater convenience to production.

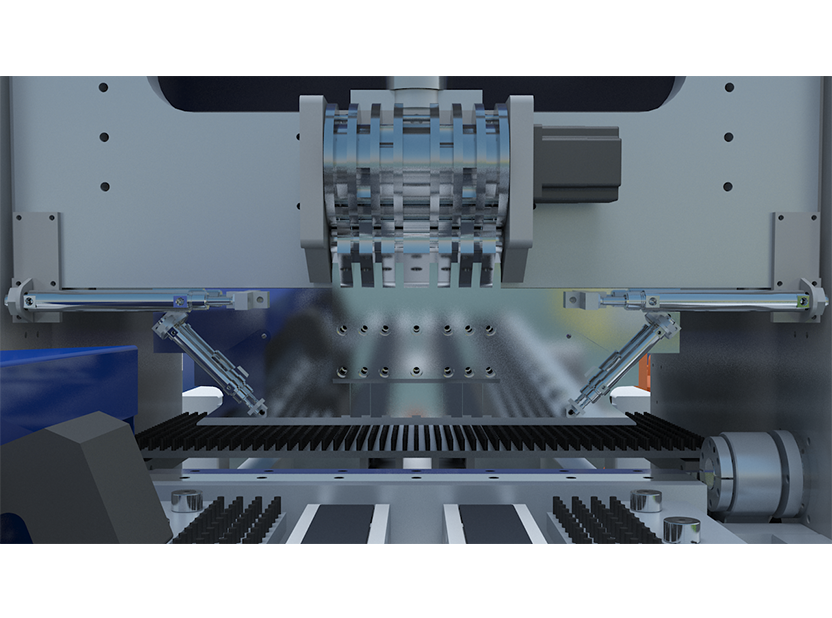

Pass-type bending

After materials are fed from the last working procedure, they directly enter X-FOLD B workstation (consisting of two edge folding machines, it passes in and out of the abdominal part of the edge folding machine, and this is different from module A) through the conveying system for bending. We can enter the next working procedure after bending is completed. This pass-type punching mode perfectly fits in with assembly lines.

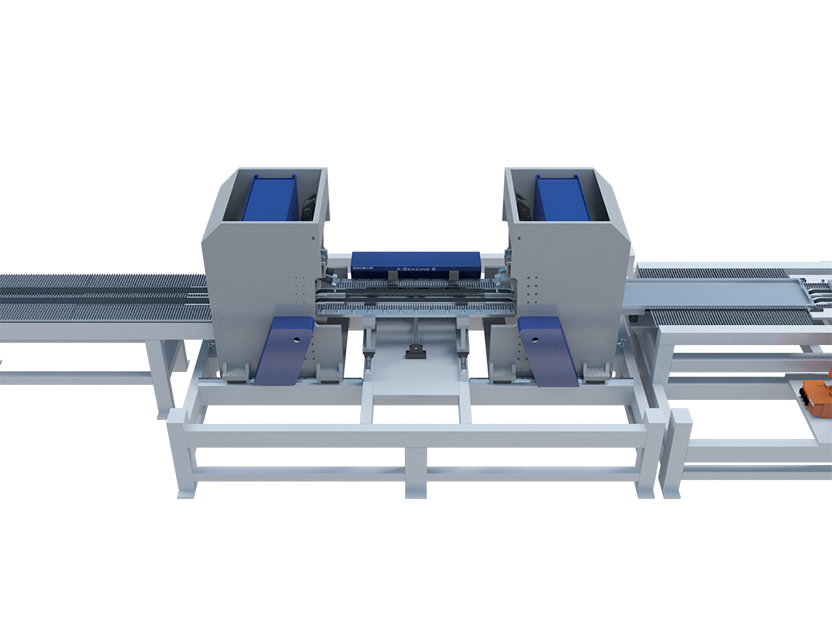

Cooperative use of X-FOLD A and X-FOLD B

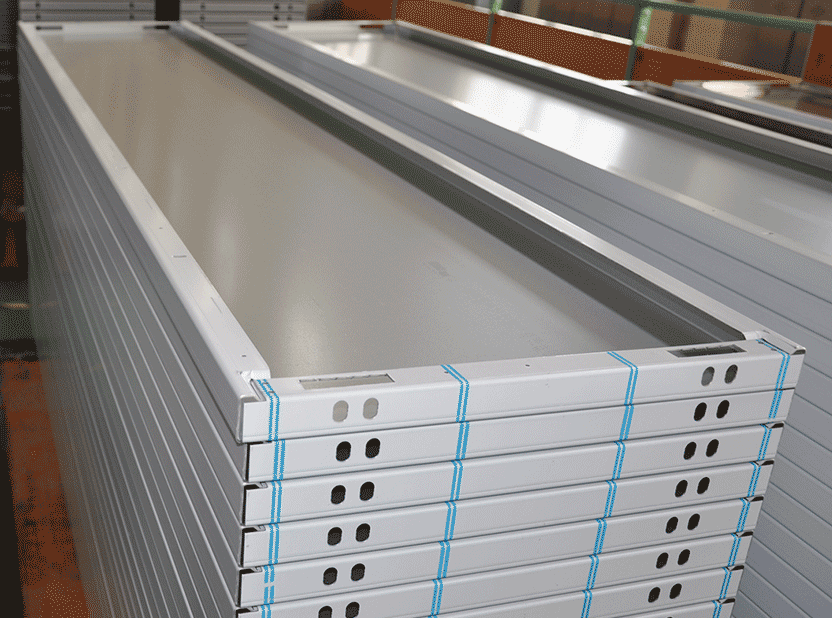

For products bent by X-FOLD B workstation, bending width is generally not greater than 1,200mm (non-standard customization should be carried out for products greater than 1,200mm). Under most circumstances, it is used cooperatively with X-FOLD A. Assembly line fabrication for four-edge bending workpiece as shown in the figure is completed.